Certifications

Plants certified ISO 9001, ISO 14001, FSSC 22000, OSHAS 18001

Legal compliance

Products conform to Food Contact legislations Traceability ensured through a Supply Chain Information system using barcodes

Food Safety Risk Management

HACCP (Hazard Analysis of Critical Control Points) & Food and Safety programs implemented on every site

Quality laboratory

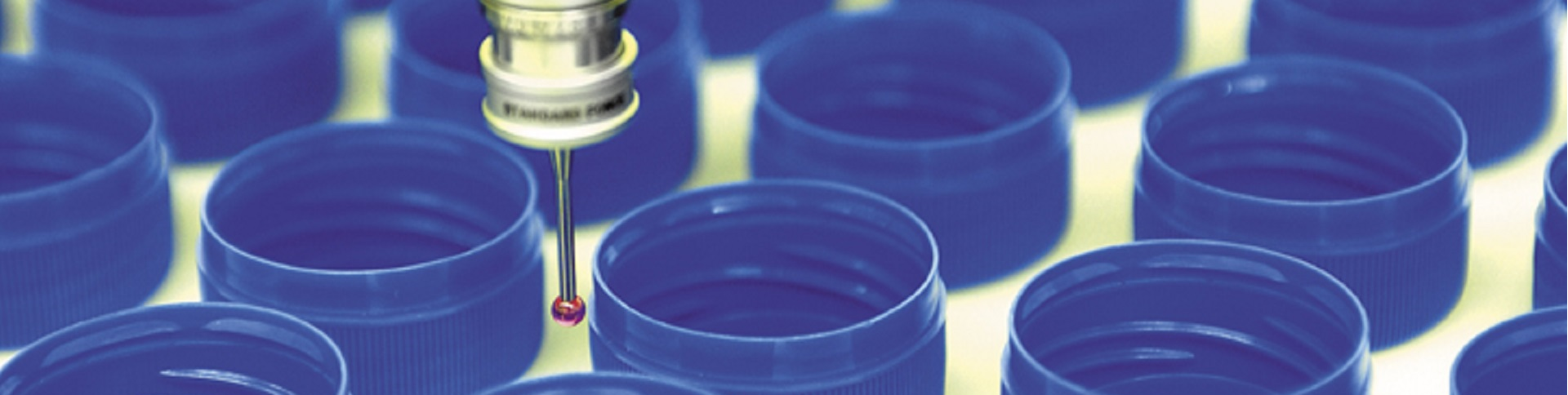

- Dimension controls with 3D Coordinate Measuring Machine.

- Organoleptic controls to prevent taste transfer.

- Bacteriological controls to ensure high hygienic standards.

- Functional performance is validated on a continuous basis.

On-line

100% of our products are inspected by vision systems (cameras). Routine controls are completed by operators.

Quality Policy

Global objectives and standards are deployed and applied in every entity.

Continuous improvement

Novembal utilizes the WCM (World Class Manufacturing) program to ensure continuous improvement.

This program is designed to improve the overall performance of the production sites by examining cost control and other areas.

Customer satisfaction is major focus of this program as are productivity, waste reduction, energy consumption and carbon footprint.

As in any Total Quality program, the development of the employee's skills are the highest priority to ensure they successfully manage their work station. Risk prevention and employee satisfaction improvement are also part of these objectives.